Advertisement

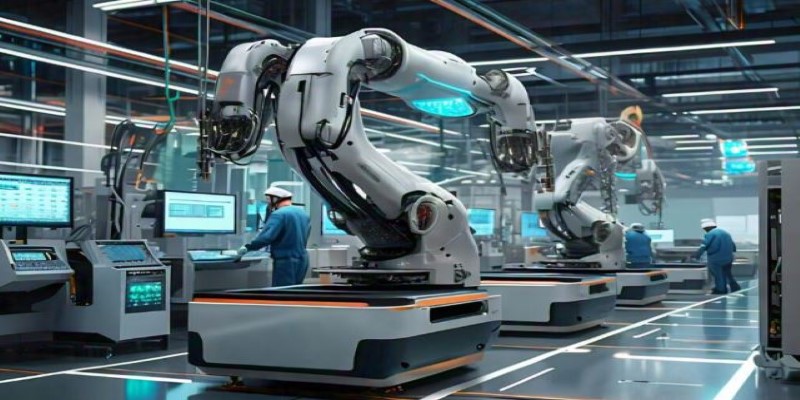

Toyota is moving forward with a new plan to bring artificial intelligence into its manufacturing plants. Through a partnership with technology firms, the company will create AI-powered smart factory tools designed to improve how vehicles are built. These tools will make production lines more precise, adaptive, and efficient, helping Toyota meet modern demands while maintaining its high standards.

Known for its focus on improvement, Toyota is now applying data-driven intelligence to achieve even better results. This partnership reflects a shift toward more automated and flexible production, where machines and humans work together more effectively than before.

Toyota has long been recognized for pushing the boundaries of manufacturing with its lean production system. That approach helped the company set standards for efficiency and reliability. But the reality of today’s industry is different—markets shift quickly, supply chains are fragile, and customer expectations keep rising. To stay ahead, Toyota is relying on AI-driven smart factory software to make factories more flexible and informed decision-makers. These tools can analyze real-time data, spot problems early, and adjust operations instantly to keep production on track.

One big advantage is predictive maintenance. Machines naturally wear down, but AI can pick up subtle signs of trouble that people might miss. Repairs can then be scheduled before anything breaks, keeping downtime to a minimum. Quality checks are also being upgraded. Instead of periodic inspections, AI-equipped cameras and sensors monitor every step, catching even the tiniest flaws as they happen. That means fewer wasted materials and better products leaving the line.

Toyota also sees potential in cutting energy waste. AI can track how power is used across the factory and recommend smarter ways to run equipment, which helps both the bottom line and the environment. This move shows Toyota understands the future of manufacturing needs to balance productivity with responsibility, meeting demand while taking care of resources.

Toyota’s smart factory tools are being designed to integrate with its current production systems without requiring a full overhaul. The rollout will begin with pilot programs at selected facilities before being scaled across more plants. Machine learning algorithms form the core of the system, analyzing production data and recommending changes in real time. For example, if robotic arms start to drift from their intended path or a machine shows signs of inefficiency, the system can make immediate adjustments.

Another element is the introduction of collaborative robots, also known as cobots, which work alongside human employees. These robots will use AI to learn from the way humans perform their tasks, helping to lighten their workload while improving overall speed and accuracy. Instead of replacing workers, these robots are designed to support them, taking on repetitive or physically demanding jobs so employees can focus on decision-making and oversight.

Supply chain monitoring will also benefit from the new tools. Real-time tracking of inventory and supplier shipments will help avoid disruptions that can stall production. If a delay is detected, the system can automatically adjust the schedule or recommend alternate suppliers. This ability to adapt quickly is particularly valuable given the global supply chain challenges many manufacturers face today. Together, these tools will create a more stable, efficient, and intelligent production process.

Toyota is working with several technology and software companies to develop these advanced tools. While not all partner names have been disclosed, they bring expertise in artificial intelligence, industrial automation, and systems integration. These partnerships allow Toyota to focus on adapting the tools to its unique production environment while relying on partners for the technical development.

This collaboration shows that AI-driven manufacturing requires more than just mechanical engineering—it also depends heavily on advanced software and data science. Toyota’s partners are providing knowledge in areas such as algorithm development, sensor technology, and cloud-based analytics. Together, they aim to build a system that not only meets Toyota's needs but can also evolve as manufacturing requirements change. By working closely with these experts, Toyota can ensure that the tools are reliable and suit its production philosophy.

Toyota's decision to invest in AI-powered smart factory tools may set an example for the wider industry. As one of the world's most influential automakers, Toyota's choices often inspire others to adopt similar strategies. If this initiative delivers on its promise of more efficient, precise, and adaptable production, other manufacturers are likely to follow suit with their own AI programs.

The shift will also change the role of workers in the factory. AI and automation will not eliminate jobs but will transform them, moving employees away from repetitive tasks and toward roles that require judgment and oversight. Employees will still be essential to ensuring that production runs smoothly, but their focus will increasingly be on supervising machines and making strategic decisions.

From an environmental standpoint, the tools have the potential to reduce emissions and cut down on waste. Smarter monitoring means fewer defective parts and less energy use, which helps meet the growing demand for more sustainable production. Toyota hopes that these improvements can align profitability with responsibility, showing that modern manufacturing can be both efficient and mindful of its impact.

Toyota’s initiative to develop AI-powered smart factory tools in partnership with technology specialists marks a clear step toward the next stage of manufacturing. The integration of intelligent systems with traditional production lines promises a factory that learns, adapts, and improves over time. Workers, machines, and data will operate in closer coordination, producing cars with greater precision and fewer disruptions. Beyond making its operations stronger, Toyota's approach may influence manufacturing practices across the industry. As this project evolves, it represents a vision of production that combines proven methods with innovative thinking, creating smarter and more sustainable ways to build the vehicles of tomorrow.

Advertisement

Learn how to boost sales with Generative AI. Learn tools, training, and strategies to personalize outreach and close deals faster

Delta partners with Uber and Joby Aviation to introduce a hyper-personalized travel experience at CES 2025, combining rideshare, air taxis, and flights into one seamless journey

How to implement Policy Gradient with PyTorch to train intelligent agents using direct feedback from rewards. A clear and simple guide to mastering this reinforcement learning method

Tech giants respond to state-level AI policies, advocating for unified federal rules to guide responsible AI use.

Looking to build practical AI that runs at the edge? The AMD Pervasive AI Developer Contest gives you the tools, platforms, and visibility to make it happen—with real-world impact

Google debuts new tools and an agent protocol to simplify the creation and management of AI-powered agents.

New to neural networks? Learn the top 3 things you must understand before you begin. This guide explains how neural networks work, why data matters, and what to expect from these learning systems

Explore the key features, benefits, and top applications of OpenAI's GPT-4.1 in this essential 2025 guide for businesses.

Explore seven advanced Claude Sonnet strategies to simplify operations, boost efficiency, and scale your business in 2025.

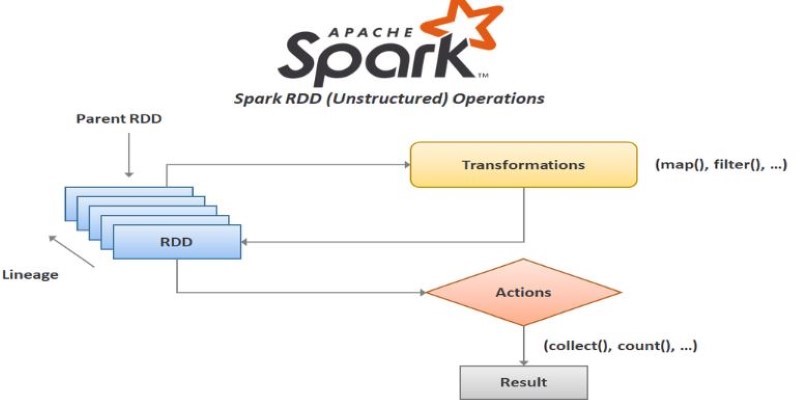

How to create RDD in Apache Spark using PySpark with clear, step-by-step instructions. This guide explains different methods to build RDDs and process distributed data efficiently

Discover why global tech giants are investing in Saudi Arabia's AI ecosystem through partnerships and incentives.

Discover how AI reshapes contact centers through automation, omnichannel support, and real-time analytics for better experiences